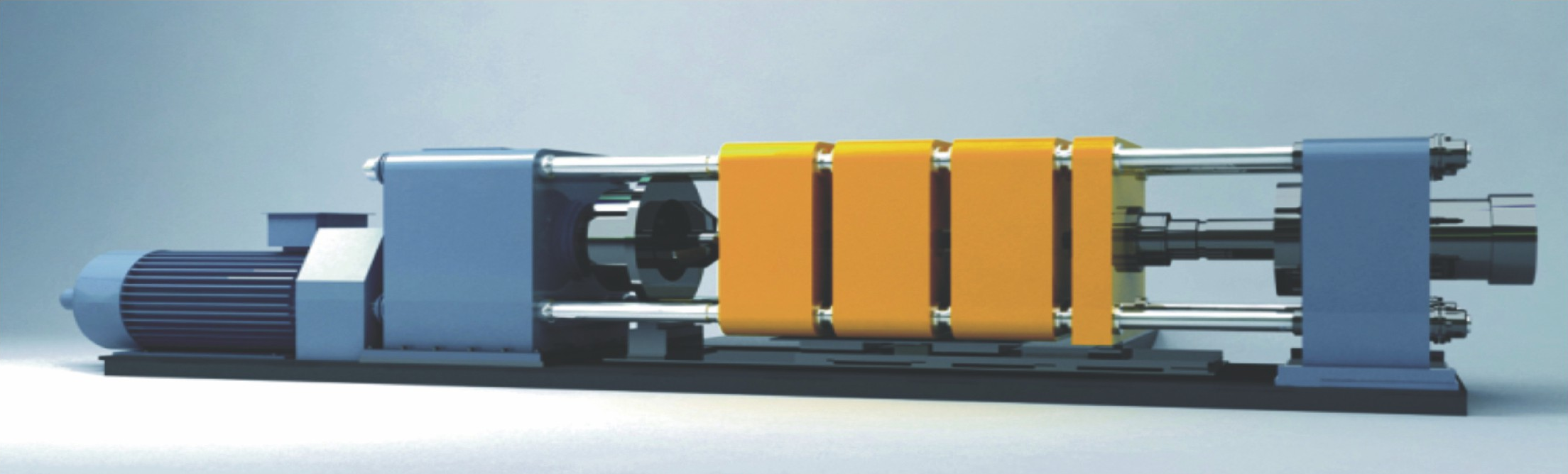

◎ Basic performance parameters:

(1) Power of driving motor of spindle: 710kW

(2) Maximum upset force: 5,000 KN

(3) Working load: 32,000N. m

(4) Welding productivity: 1 piece every 5~10 minutes

(5) Speed of spindle: 120-200 r/min (stepless speed regulating)

(6) Stroke of spindle box: 500 mm

(7) Eccentric distance of weldment: ≤1.2mm

(8) Phase error: <1°

(9) Weldable workpieces: Low-carbon steel, low alloy steel and pure aluminium

◎ Innovation points:

※ A clamp dedicated for cast steel claws ensures reliability of welding.

※ A heavy-load spindle rotation clamping and pressure device is developed, ensuring upset forces required by welded workpieces during welding and improving welding strength and uniformity.

※ High-tonnage welder phase control technology is developed, satisfying phase requirements of the welded workpieces and producing high-quality welded joints.

◎ Performance advantages of products

(1) Direct connection between an aluminium guide rod and a cast steel claw is achieved, lowering resistance of welded joints, effectively improving conductivity and accomplishing the goals of energy conservation and cost reduction (voltage reduction by about 6mV).

(2) High efficiency

(3) High welding strength and uniformity

(4) No dust, spatter or arc light is produced during welding; therefore, it is environmentally friendly.

(5) No accessories (e.g., welding rods, welding wires, welding flux and shielding gas) are used during welding, saving the labor cost and significantly reducing the production cost.

◎ Promotion and application:

5000 Kn friction welding machine for special purpose is developed for the first time in China; and, it is undergoing pilot tests in Aluminium Corporation of China, Liancheng Branch.